In the dynamic landscape of electronics manufacturing, optimizing processes is paramount to achieving efficiency. Manufacturers are constantly seeking ways to decrease production times, improve product quality, and automate workflows. By adopting innovative technologies and best practices, manufacturers can attain significant gains in overall performance.

- One aspect of optimization involves utilizing automation technologies to automate repetitive tasks.

- Another, manufacturers can utilize data analytics to identify areas for improvement and make data-driven decisions.

Smart Factories : The Future of Electronics Production

The electronics industry is on the cusp of a revolution, driven by the rise of smart factories. These innovative facilities leverage robotics to optimize production processes, enhance efficiency, and minimize costs. With integrated systems collecting real-time data, smart factories gain unprecedented visibility into every aspect of the manufacturing process. This allows for proactive repairs of potential issues, minimizing downtime. Moreover, smart factories enable personalization, allowing manufacturers to seamlessly adjust to evolving market demands and produce highly specialized electronics.

Streamlining Logistics in Electronics Manufacturing

The electronics manufacturing industry heavily depends on efficient global distribution networks. A robust system is essential for procuring raw inputs, assembling electronic devices, and shipping them to consumers in a timely and.

- Obstacles in the electronics manufacturing supply chain include:

- Global sourcing

- Fluctuating demand

- Time-sensitive deliveries

- Stock management

Implementing innovative supply chain practices can enhance the profitability, stability and responsiveness of electronics manufacturing operations.

Eco-Friendly Practices in Electronics Assembly

The electronics assembly industry plays a crucial role in our globalized world. However, it also presents concerns regarding its environmental impact. Implementing green practices during the assembly process is essential electronics manufacturing to minimize this impact and ensure a more sustainable future.

- Many initiatives are being adopted by manufacturers to reduce their burden. These include the use of clean energy sources, streamlined manufacturing processes, and the minimization of hazardous waste.

- Furthermore, alliances between industry stakeholders, researchers, and regulatory bodies are accelerating the development and adoption of even more innovative sustainable solutions.

Through adopting these practices, the electronics assembly industry can make a difference in creating a more sustainable world for generations to come.

5. Advanced Materials and Their Impact on Electronics Fabrication

The rapid evolution of electronics fabrication hinges heavily on the emergence of cutting-edge materials. These high-performance materials enable manufacturing processes to achieve unprecedented levels of miniaturization, efficiency, and functionality. From transparent substrates to nanomaterials, these breakthroughs are revolutionizing the design and capabilities of electronic devices, paving the way for more powerful gadgets and transformative technologies.

PCB Design and Layout for High-Volume Manufacturing

Optimizing layouts for high-volume manufacturing requires careful consideration of numerous factors. Efficient trace placement strategies minimize component density while ensuring signal integrity. Utilizing standardized components and a hierarchical design approach enhances manufacturability and reduces production costs. Adhering to industry best practices, such as IPC standards, guarantees consistent quality and reliability across large-scale runs. Furthermore, implementing robust DFM (Design for Manufacturing) guidelines throughout the workflow helps mitigate potential manufacturing challenges and ensures smooth implementation.

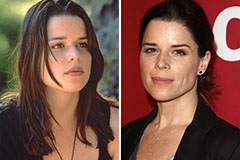

Neve Campbell Then & Now!

Neve Campbell Then & Now! Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Andrew Keegan Then & Now!

Andrew Keegan Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!